How the Optical Fibre Diameter Analyser Plays a Vital Role in Enhancing Fibre Optic Technologies

How the Optical Fibre Diameter Analyser Plays a Vital Role in Enhancing Fibre Optic Technologies

Blog Article

Understanding the Capability of an Optical Fibre Diameter Analyser in Modern Production

The optical Fibre Diameter analyser offers as an essential instrument in modern production, supplying exact, non-contact measurements that are necessary for keeping stringent sector standards. By leveraging sophisticated laser technology, these analysers not only make sure minimal signal loss but likewise improve the overall performance of optical fibres.

Value of Optical Fibre Dimension

In modern-day production, the measurement of optical Fibre Diameter is vital for ensuring the efficiency and integrity of Fibre optic systems. Precise Diameter measurement directly influences optical performance, as variants can cause boosted signal loss, reduced bandwidth, and reduced general efficiency. The optical homes, including light transmission and signal honesty, are extremely sensitive to the Fibre's Diameter, demanding exact control throughout production.

In addition, standardization in Fibre Diameter is crucial for compatibility and interoperability within varied telecommunications networks. As these networks broaden around the world, preserving uniformity in Fibre qualities advertises smooth assimilation throughout numerous parts and systems. Additionally, adhering to market standards concerning Diameter tolerances is important for makers to meet regulatory demands and customer expectations.

Spending in innovative dimension innovations not just improves producing effectiveness but additionally supports quality control processes, enabling makers to identify issues early in manufacturing. This positive technique reduces waste and guarantees that the end products fulfill rigid performance standards. The importance of optical Fibre dimension can not be overstated, as it offers as a structure for premium, reputable Fibre optic systems, which are essential to contemporary communication framework.

Exactly How Diameter Analysers Job

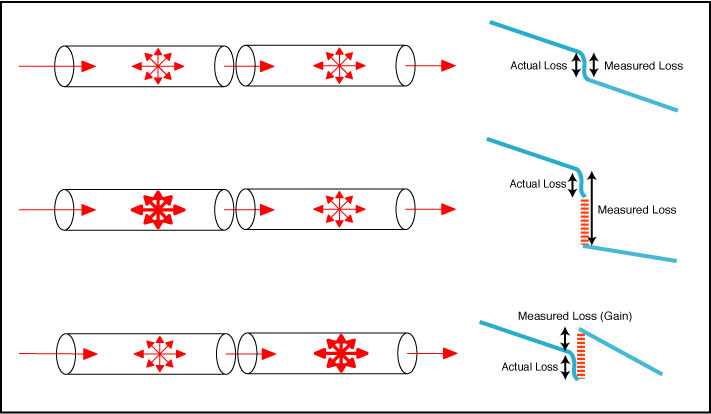

The core operation depends on the principle of light scattering and reflection. As the laser light beam strikes the Fibre, variations in Diameter reason adjustments in the light's strength and wavelength (optical fibre diameter analyser). This data is refined in real-time making use of sophisticated formulas that equate the optical signals into exact Diameter dimensions

Additionally, several Diameter analysers are furnished with several dimension points along the Fibre, enabling for a detailed evaluation of Diameter consistency. This is critical in making certain that the optical fibres satisfy stringent sector criteria. The whole process is automated, allowing high-speed dimensions and reducing human error. The implementation of such technology considerably enhances top quality control in production, ensuring that optical fibers are created to exact specifications for ideal performance in their intended applications.

Key Functions to Consider

When choosing an optical Fibre Diameter analyser, numerous key functions call for cautious consideration to guarantee ideal efficiency and reliability. Measurement precision is paramount; the analyser needs to give exact Diameter analyses, normally in micrometers, to satisfy stringent production requirements. In addition, a large measurement variety boosts flexibility, fitting different Fibre kinds and densities.

Another crucial function is the analyser's speed. Rapid dimension capacities enable boosted throughput, necessary in high-volume manufacturing atmospheres. Real-time information handling and comments capabilities enable prompt changes, enhancing quality control.

User user interface and software application compatibility are also substantial factors to consider. An user-friendly user interface simplifies operation, while robust software program support promotes data evaluation and combination with existing manufacturing systems. The capacity to export data in numerous styles can boost coverage and conformity efforts.

Moreover, durability and upkeep requirements must be assessed. An analyser created from premium products will hold up against the rigours of a manufacturing setting, while ease of maintenance ensures durability and lowers downtime. Finally, consider the degree of technological support and training supplied by the manufacturer, as this can substantially influence the reliable usage of the analyser in manufacturing settings.

Advantages in Manufacturing Efficiency

Enhancing manufacturing performance rests on the integration of advanced innovations, such as optical Fibre Diameter analysers. These tools play a pivotal function in making certain that optical fibers meet strict high quality requirements, which is crucial for optimal performance in various applications - optical fibre diameter analyser. By offering real-time measurements of Fibre Diameter, makers can promptly recognize and correct variances from specified tolerances, thereby decreasing waste and lessening the danger of malfunctioning items

Moreover, the early detection of possible problems leads to lowered downtime and maintenance costs, consequently maximizing source allocation. Inevitably, the performance gains realized with using optical Fibre Diameter analysers contribute to a much more competitive production environment, ensuring that companies can supply high-grade products while keeping cost-effectiveness and responsiveness to market needs.

Applications Across Industries

The convenience of optical Fibre Diameter analysers expands past making effectiveness, finding applications throughout numerous markets that count on optical Fibre modern technology. In telecommunications, these analysers are vital for making certain the ideal performance of Fibre optic cables, straight impacting information transmission rates and network reliability. By accurately gauging Fibre diameters, operators can reduce signal loss and boost overall communication high quality.

The medical sector additionally profits considerably from these gadgets, particularly in the advancement of endoscopic devices and laser go now therapies. Precise Diameter measurements are essential for developing effective optical fibres that are utilized in minimally invasive treatments, boosting client end results through boosted imaging and therapy capacities.

In aerospace, the analysers play an essential function in the news production of light-weight, high-strength materials, where Fibre optics are integrated into architectural components for tracking and diagnostics. Furthermore, the automotive sector utilizes these gadgets to ensure the stability of Fibre optic sensing units that boost safety and efficiency functions in lorries.

Final Thought

Finally, the optical Fibre Diameter analyser is crucial for modern-day production, guaranteeing exact measurements that support market standards. Its advanced laser technology and real-time data handling capabilities enhance quality control and operational performance. By automating the dimension procedure, producers can promptly identify variances, therefore minimizing signal loss and production downtime. The diverse applications across numerous sectors highlight the analyser's relevance in promoting constant renovation and data-driven decision-making within the manufacturing industry (optical fibre diameter analyser).

In modern-day production, the measurement of optical Fibre Diameter is critical for making certain the performance click this link and dependability of Fibre optic systems. The importance of optical Fibre measurement can not be overemphasized, as it serves as a structure for top notch, reliable Fibre optic systems, which are essential to modern-day interaction facilities.

Diameter analysers employ innovative optical innovations to properly determine the Diameter of optical fibers.In addition, many Diameter analysers are geared up with numerous measurement factors along the Fibre, permitting for a detailed assessment of Diameter consistency.The adaptability of optical Fibre Diameter analysers extends beyond producing efficiency, finding applications across various sectors that depend on optical Fibre innovation.

Report this page